tel

tel

tel

tel

tel

tel

tel

tel

2023-04-24 11:54:23

Food industry

Fruits and vegetables contain 80% to 90% moisture. Therefore, its spectral response characteristics are mainly reflected in the water absorption band, with a peak at approximately 1450 nm. Due to its strong light absorption ability, the imaging results of water content in the shortwave infrared band are significantly darker.

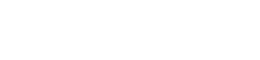

Food Analysis and Sorting

Each food has its unique chemical composition, therefore it exhibits unique spectral characteristics in both visible and shortwave infrared spectra. A shortwave infrared camera equipped with InGaAs sensors can perform online inspection of food on the conveyor belt. Spectral analysis is one of the most commonly used methods for food analysis. But the latest development trends in the food industry indicate the increasing rise of hyperspectral and multispectral imaging. This method combines digital imaging and spectral analysis technology to obtain detailed information across multiple electromagnetic spectrum ranges. The reflectance and absorptivity of certain wavelengths depend on the chemical composition and molecular structure of the food.

Short wave infrared cameras are typically used in pushbroom imaging systems, paired with spectrometers (hyperspectral imaging). If the number of bands distinguished for certain materials is small (<10), multiple bandpass filters or specialized lighting devices (multispectral imaging) can be added.

Metal and Glass Industry

Short wave infrared cameras can provide thermal imaging of high-temperature objects between 250 ° C and 800 ° C. The metal and glass industries have introduced shortwave infrared cameras into their processes and quality control systems.

Monitoring and Inspection of Molten Metal Processes

Compared to CCD and CMOS cameras, InGaAs cameras typically have a spectral range of 900 nm to 1700 nm, which can detect emission spectrum differences between molten iron and slag. Based on this information, slag differences in the manufacturing process can be detected. This feature helps to maximize production capacity while avoiding any contamination of materials.

Glass bottle monitoring and inspection

In the production process of glass bottles, InGaAs cameras can be used for internal and external inspection. Short wave infrared cameras can provide thermal imaging of high-temperature objects between 250 ° C and 800 ° C, and can monitor glass temperature uniformity and cooling rate. Therefore, manufacturers can use it to continuously observe production conditions and maximize production and quality.

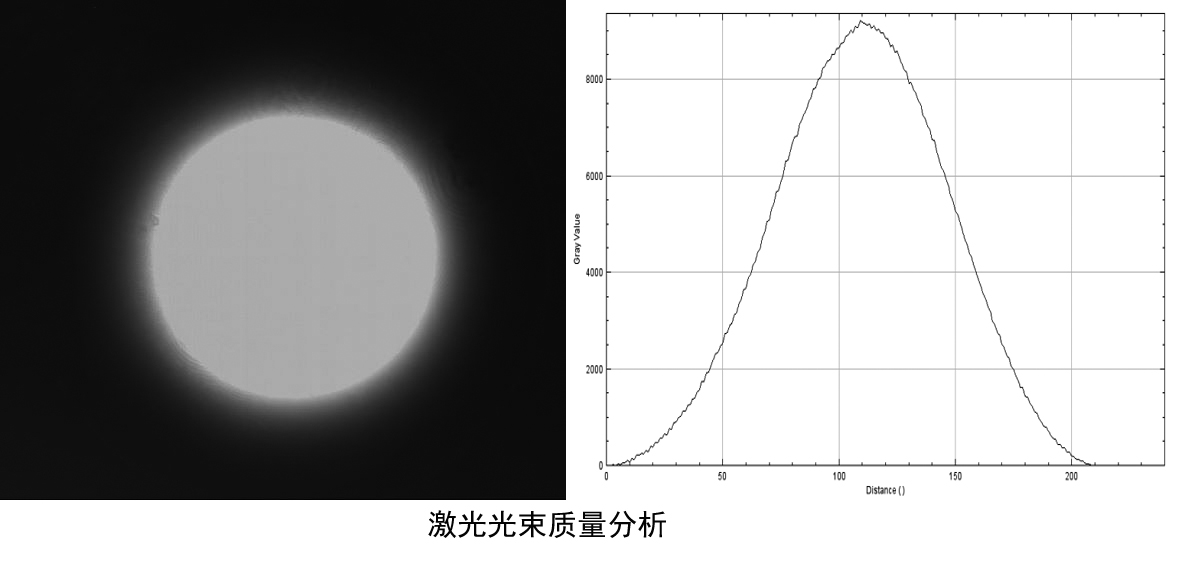

Laser beam analysis

Laser applications are vast and vast. For example, material welding and cutting, medical applications, spectral analysis, and surveying. If applied properly, lasers are a rare weapon. But as the usage time and frequency increase, the performance and efficiency of the laser will gradually decrease. To ensure the stability of the emitted laser signal, telecommunications companies have started using laser beam analysis equipment called spectral analyzers. To ensure efficient utilization of laser, it is crucial to monitor parameters such as beam position, size, power, and laser beam spectrum, and ensure compliance.

The spectral range of short wave infrared wavelength lasers is invisible to the naked eye. The beam analyzer based on InGaAs sensors is an ideal choice for laser measurement and analysis in short wave infrared wavelengths between 900 and 1700 nm.

Agriculture

Spectral imaging can also be used for agricultural purposes, especially when used in conjunction with unmanned aerial vehicles (UAVs). Farmers can use this technology to remotely inspect crops, such as strawberry fields: by observing shortwave infrared images, they can identify plants or areas that are lacking in water, with good or excessive water content. The higher the detected moisture content, the higher the absorption peak at 1450 nm wavelength, and the darker the corresponding area in the image. Therefore, such applications typically use narrower 1450 nm bandpass filters to enhance this effect.

Airborne remote sensing

Drones are particularly commonly used in agriculture, but they can also be used for other purposes, such as inspecting multiple materials from the air. Each inorganic material has a unique chemical composition and crystal structure, resulting in a unique spectral response corresponding to its specific light absorption characteristics.

Geological and mineral inspection

By utilizing unique spectral responses, mineral distributions around the world can be mapped. In addition, forestry companies can also use this technology to draw forest land maps. Hyperspectral imaging can utilize methods similar to food analysis to assist in geological and mineral exploration.

In the future, the application field of shortwave infrared cameras will further expand, and the development of sensor technology plays an important role in it. In individual cases, some applications can only use one camera, while sensors that extend beyond the visible spectral range (400 nm-1700 nm) can help reduce system complexity. A camera with shortwave infrared sensitivity extended to the 2500 nm range can detect other types of materials or features. Finally, sensors with smaller pixel sizes can also capture objects with higher spatial resolution and lower cost.

Sales Manager: Lily Liu

Mobile: 086-13359283296

Email: info@gatherstarhk.com

Xi'an Gatherstar Optoelectronic System Co.,Ltd is specialized in infrared and laser photoelectric system products and module, components and elements. we are not only confident in supplying qualified optoelectronic products to all of our customers, but also concentrating on offering continuous innovations and reliable service.